From variable-area to magnetic up to single-use to Coriolis, there’s a lot of options when it comes to choosing a flowmeter device. However, each option has unique differences in price, accuracy, and functionality.

Ultrasonic meters that are non-invasively and accurately measured by the commonly utilized tubing is the best multi-use option. Yet, it comes with an expensive price tag. If you’re looking for something affordable but accurate, then single-use turbine meters are an excellent option, especially in dealing with low viscosity fluid.

When choosing a measuring device, you need to consider the:

- Type of fluid

- Flow measurement type

- Flow range

- Fluid conditions

- Environmental factors

- Accuracy

For a little help, we’ll walk you through several meter options that may work best for your application. So, take a read!

Vortex Flowmeters

This device makes use of a pressure sensor to calculate or gauge the pressure pulses from vortices that derive from the media or fluid flowing through bluff bodies over the flow stream.

The pressure pulses are proportionate to the flow rate. A lot of users find the vortex type of these devices as appealing and pleasant since it has no moving components. Plus, it has a low vulnerability to changes in process conditions.

Even if a lot of people are unfamiliar with this technology, the vortex meter is an option that provides accurate results. Since the vortex bar and meter body can be shaped like one, the design is suitable for use in either high-purity or aggressive applications.

Vortex flowmeters work well in the food and beverage, wastewater, and oil and gas industries. Also, they can be used in water purification, chemical manufacturing, and utilities.

Variable Area Flowmeters

This device is the most commonly used and a veteran in the industry. They are also called as rotameters. The variable area flowmeters’ design comprises of a spherical float covered in a tube.

The float reacts to variations in the fluid’s velocity by moving the flow tube up or down. The operating principle of this instrument is: when fluid flow velocity lifts or elevates a float enclosed in a tube, it increases the area of the fluid passage.

The more the flow, the towering the float rises. The float’s height is directly proportional to the rate of flow. Just read the graduated markings at the float’s center to determine the flow. Rotameters can be utilized in industrial and laboratory applications.

And compared to other meter types, variable area flowmeters are the most economical for determining flow rate measurement, with regards to accuracy and practicality. This meter device is leveraged in science laboratories for both education and experimentation purposes.

Moreover, a variable device can be used in chemical manufacturing, beverage manufacturing, oil and gas applications, aquafarms, and water purification. However, take note that this meter type must not be applied with fluid that could coat the measuring tube or the float. For more information check smartmeasurement.com.

Ultrasonic Flowmeters

This kind of device provides greater versatility and more advanced technology compared to other measuring instruments. Ultrasonic meters gauge the frequency shift of a sonic signal that’s conveyed through the fluid.

There are two ultrasonic flowmeters types: Doppler ultrasonic meter and transit-time ultrasonic meter. Transit-time ultrasonic one depend on a frequency variation in reverse, and forward signals conveyed through a clean liquid to calculate the fluid’s velocity.

Take note that the clean fluid mustn’t have aeration or solids because they’ll deform the sonic pulses. When modifying piping isn’t feasible, ultrasonic flowmeters are ideal for establishing flow profiles via an existing process.

Since this device is extremely versatile, ultrasonic meters are applied in many industries such as mining, pulp and paper manufacturing, and facilities management.

Turbine Flowmeters

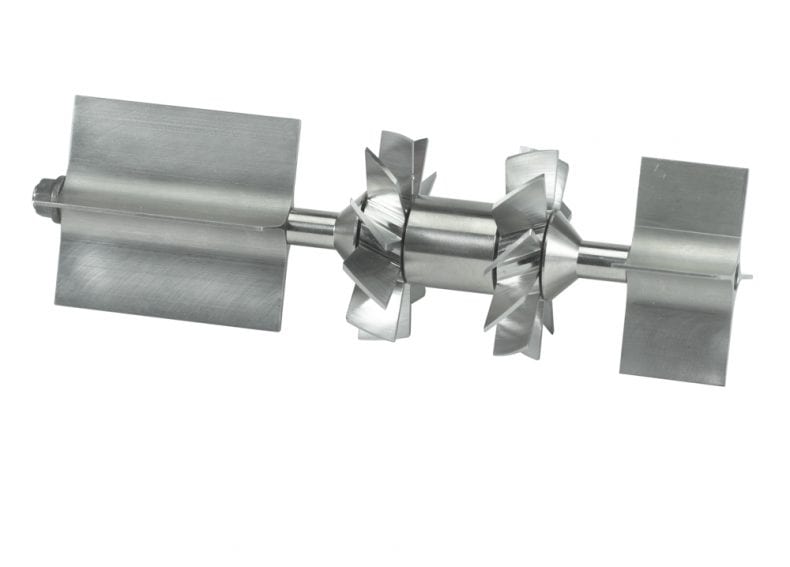

This type of device has a bladed rotor situated along the flow stream’s center line. The bladed rotor is, for the most part, designed to give a pulse when passing an optical or magnetic sensor.

The pulses frequency is equal to the fluid’s velocity. Some turbine meters provide high accuracy and can deal with higher viscosity fluids compared to the propeller designs. Moreover, some designs satisfy sanitary protocols.

Water purification and irrigation are two generally known turbine meters applications. Also, they can be applied in wastewater, utilities, and oil and gas industries. If you’ll apply it with sanitary connections, this flowmeter manages flow in the food and beverage industries.

Takeaway

The abundance of flowmeter options can make choosing the right one for your application a challenging task. And when it comes to the actual selection process, there are many factors to consider, and the cost is just a part of it. The following are some tips for choosing the right device for your application:

- Know if your industry requires a flowmeter.

- Don’t pick based on the cost alone.

- Learn your flow.

- Choose one with the widest turndown.

- Consider installation.

- High-accuracy.