When it comes to our car, we all learn the basics early on. We’re taught how to add oil, change a tyre and give it a jump start.

But what about the wiring? Would you know what to do with the wiring once the bonnet is popped? Finding out how the wiring works can potentially save you money on calling out a mechanic as well as boosting your auto knowledge.

So, if you could do with knowing the nuts and bolts of the electrics in your motor, here are the top tips to help.

Tools of the Trade

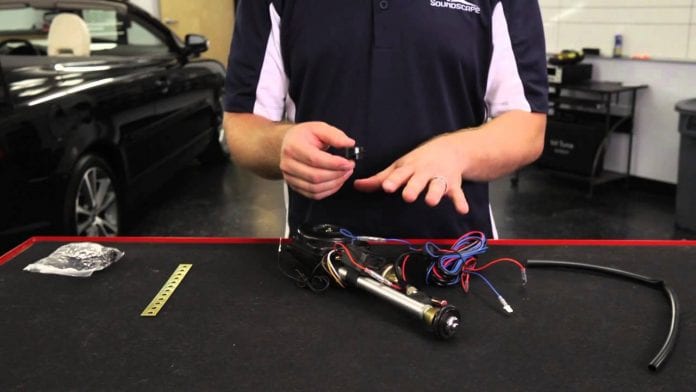

Before you begin your DIY wiring journey, it’s important to have all the materials you will need for the job so that you can smoothly carry out the wiring process. For any type of electrical work, the essentials you will need include a soldering iron and wire strippers. A digital multimeter is also ideal for checking you have the right wires.

As well as these tools, you will also need specialist wire for your car, which is available from suppliers such as RS Components, solder connectors, gauge wire and some type of electrical wire to hold everything in place.

Carry out Checks

Familiarise yourself with the circuits. Use a wiring diagram for your car if possible as this can act as your map as you work on the electrics and find the relevant wires. At this stage, you can use your digital multimeter to check for the proper voltage and circuit polarity.

Once you feel you know the circuits and the current have been checked, you can then disconnect the battery. This is crucial for any wiring work, and it should only be reconnected if you’re testing wires or equipment.

Do make sure to check that disconnecting the battery doesn’t trigger anti-theft protection. If it does, it’s worth having the reset code ready, which can usually be found in the car manual.

Things to Use

There are several key items you will need to use next. Firstly, wire strippers can be used to peel back the layers of insulation safely and without running the risk of cutting into the wire.

Next, get soldering! If you need to solder wires and have the equipment ready, you should be able to join the wires enough to withstand daily driving. Should soldering not be something you feel confident about, butt connectors can be used to slide the stripped-back wires into. You can then squeeze the connectors with a crimping tool to join the wires together.

Once you’ve soldered or butt connected your wires, use the electrical tape or some heat shrink to insulate the wires. This protects them from corroding or shorting.