The food and beverage industry relies heavily on maintaining high-quality and safety standards. One critical component in achieving these standards is the use of pure gases in various processes. Nitrogen plays a key role in this regard. It is utilized in many applications such as packaging, preservation, and carbonation. Ensuring a consistent and pure supply of nitrogen is crucial, and PSA nitrogen generators are essential in this context.

Nitrogen generator for food industry applications ensures a steady supply of high-purity nitrogen, which is vital for maintaining the integrity and quality of food and beverages. These generators use Pressure Swing Adsorption (PSA) technology to produce nitrogen on-site, offering several advantages over traditional methods of nitrogen supply, such as gas cylinders or liquid nitrogen tanks.

Understanding PSA Technology

PSA technology operates by separating nitrogen from other gases present in the air. This process involves two vessels filled with a carbon molecular sieve, which adsorbs oxygen and other gases under high pressure, allowing it to pass through. When the pressure is reduced, the adsorbed gases are released, and the sieve is regenerated. This cycle continues, providing a continuous supply.

Benefits

Cost Efficiency

On-site nitrogen generation reduces the need for frequent deliveries of cylinders, lowering transportation costs and minimizing disruptions. Companies can produce the exact amount of nitrogen they need, reducing waste and optimizing costs.

Purity and Consistency

On-site generators ensure a consistent supply of high-purity. This is crucial for applications like packaging and preservation, where even slight impurities can affect product quality and shelf life.

Environmental Impact

By generating nitrogen on-site, companies reduce their carbon footprint. There are fewer emissions from transportation, and the process itself is energy-efficient, contributing to sustainability goals.

Applications in the Food and Beverage Industry

Packaging

It is commonly used in modified atmosphere packaging (MAP) to displace oxygen, which can cause oxidation and spoilage. By usingthis element, the shelf life of packaged foods is extended, maintaining freshness and quality.

Preservation

Nitrogen is used to blanket storage tanks and containers, preventing oxidation and contamination. This is particularly important for beverages like wine and beer, where exposure to oxygen can affect taste and quality.

Carbonation

In the beverage industry, nitrogen can be used to carbonate drinks, offering a smooth and stable carbonation process. This is an alternative to carbon dioxide, providing a unique texture and taste.

Case Studies

Dairy Industry

A major dairy producer implemented PSA generators to improve their packaging process. By switching to on-site nitrogen generation, they reduced costs by 20% and saw a significant improvement in product shelf life. The use of high-purity nitrogen in their modified atmosphere packaging allowed them to maintain the freshness of their dairy products for longer periods, meeting consumer demands for high-quality and fresh products.

Brewing Industry

A craft brewery utilized PSA technology to enhance their beer carbonation process. The use of nitrogen provided a smoother mouthfeel and improved taste, setting their product apart from competitors. The brewery also benefited from the cost savings associated with on-site nitrogen generation, allowing them to invest in other areas of their business.

Snack Food Industry

A leading snack food manufacturer adopted PSA nitrogen generators to improve the quality and shelf life of their products. By using nitrogen to displace oxygen in their packaging, they were able to prevent the oxidation of oils and fats, which can lead to rancidity. This resulted in a significant extension of the shelf life of their products, reducing waste and increasing customer satisfaction.

Meat Processing Industry

In the meat processing industry, maintaining the freshness and safety of products is crucial. One company implemented PSA nitrogen generators to improve their preservation methods. By using nitrogen to create a modified atmosphere in packaging, they were able to significantly extend the shelf life of their meat products. This not only reduced waste but also improved the quality and safety of their products, ensuring customer satisfaction and compliance with stringent health regulations.

Bakery Industry

A well-known bakery chain adopted PSA nitrogen generators to enhance the quality of their baked goods. By using nitrogen in the packaging process, they were able to keep their products fresh for longer periods. This innovation allowed the bakery to expand its distribution network, reaching more customers without compromising on product quality. The cost savings from reduced spoilage also enabled them to invest in new product development.

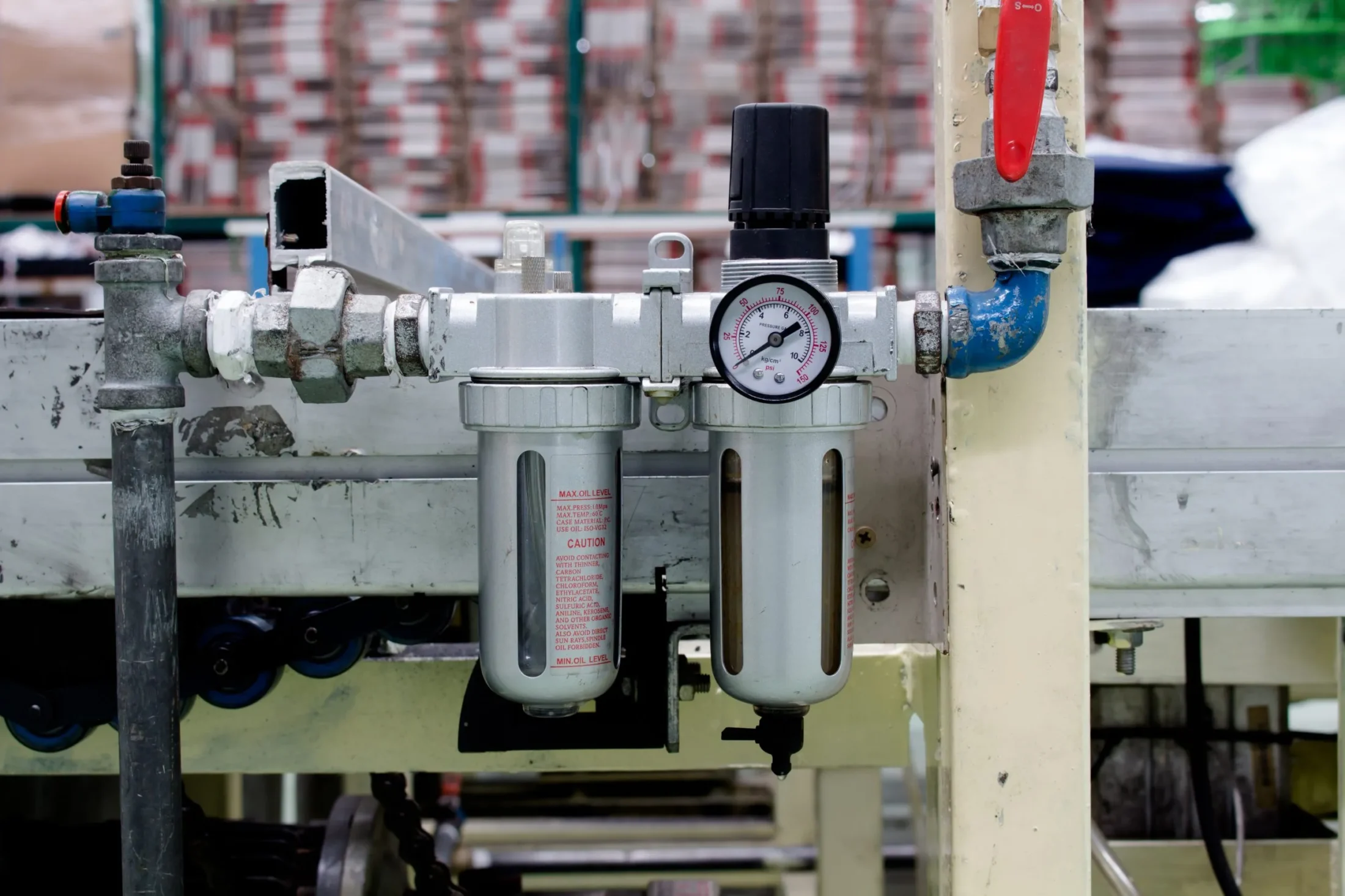

Maintenance and Reliability

PSA nitrogen generators are designed for reliability and require minimal maintenance. Regular checks and simple maintenance routines ensure consistent performance. Most generators come with advanced monitoring systems that provide real-time data on purity levels and system performance, allowing for proactive maintenance. These systems can alert operators to any potential issues before they become critical, ensuring a continuous supply of nitrogen without interruptions.

Future Trends

As the food and beverage industry continues to evolve, the demand for on-site nitrogen generation is expected to grow. Innovations in PSA technology will likely lead to more efficient and compact systems, making it easier for small and medium-sized enterprises to adopt this technology. Additionally, the increasing focus on sustainability will drive the adoption of on-site nitrogen generation as a greener alternative to traditional methods.

The integration of smart technology in PSA nitrogen generators is another trend to watch. Smart systems can optimize the operation of the generator, ensuring maximum efficiency and minimal energy consumption. This can lead to further cost savings and a reduced environmental impact. Moreover, the use of IoT (Internet of Things) can enable remote monitoring and control of the generators, providing greater flexibility and control over production.

Conclusion

PSA offer numerous benefits to the food and beverage industry, from cost savings and consistent purity to environmental sustainability. By understanding and leveraging this technology, companies can improve their processes, enhance product quality, and contribute to a more sustainable future. With the growing demand for high-quality and safe food and beverages, the role in the industry is more critical than ever, and PSA provide a reliable and efficient solution.

By following these guidelines and maintaining strict adherence to purity standards, the food and beverage industry can ensure the highest quality products, meet regulatory requirements, and achieve operational efficiency. The adoption of PSA nitrogen generators is a strategic investment that can deliver significant returns in terms of product quality, cost savings, and environmental sustainability.

The continued advancements in PSA technology and the increasing focus on sustainability are set to drive the future growth of on-site nitrogen generation in the food and beverage industry. As more companies recognize the benefits of this technology, its adoption will likely become more widespread, further enhancing the quality and safety of food and beverage products worldwide.