In the fast-paced world of the food and beverage industry, accuracy is everything. And when it comes to ensuring quality control, there’s no room for error. That’s where counting scales come in – these handy tools play a crucial role in accurately measuring ingredients and portions, helping to maintain consistency and prevent waste.

Ensuring Accurate Ingredient Weighing

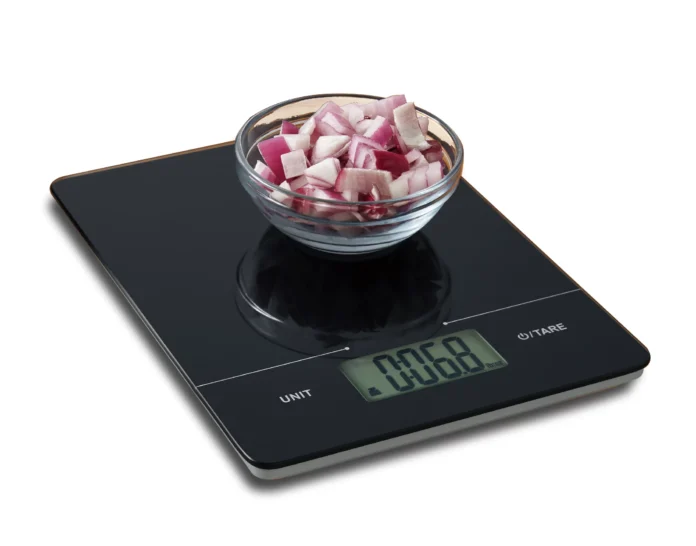

Accurately weighing ingredients is crucial in the food and beverage industry to maintain product quality and consistency. With the help of counting scales, businesses can ensure precise measurements while saving time and reducing waste. Here’s a simple 5-step guide to ensuring accurate ingredient weighing:

- Choose the right counting scale for your needs

- Calibrate the scale before use

- Use standardized containers for measuring ingredients

- Weigh ingredients separately to avoid errors

- Regularly perform maintenance on the scale to ensure accuracy

In addition, counting scales from SWSCALE also offer features such as tare functions, piece counting, and memory recall that can further improve weighing accuracy. By implementing these measures, businesses can save money by reducing food waste and increase customer satisfaction by consistently delivering high-quality products.

Maintaining Consistency in Product Quality

One way to achieve this is by incorporating counting scales into production processes. These scales accurately measure ingredient quantities, ensuring that each batch has the same amount of ingredients, resulting in consistent product quality. By using counting scales, businesses can improve efficiency, reduce waste, and provide customers with a reliable and repeatable experience.

Scales also have benefits beyond just maintaining consistency in product quality. They help companies track inventory levels, detect discrepancies in ingredient amounts, and prevent overproduction or under-production. This can lead to overall cost savings for the business as it prevents overbuying ingredients that may expire before being used or results in not having enough finished products to meet customer demand.

These tools are particularly important for small businesses where even small variations can greatly affect the final product’s taste and texture as they typically do not have automated measuring tools like larger corporations. With such precise measurements provided by a scale, small businesses can increase their competitive edge by offering high-quality products consistently.

Meeting Regulatory Standards

Meeting the guidelines established by regulatory bodies is essential in the food and beverage industry. Scales play an important role in meeting these standards by providing accurate and precise measurements. This ensures that products are consistent in size, weight, and volume as required by relevant authorities.

Maintaining compliance with safety regulations is paramount to avoid penalties and loss of reputation. Broken or inaccurate scales can result in inaccurate measurements and affect food quality tremendously. Counting scales also come equipped with advanced features like tare weights which eliminates the error caused due to packaging materials or containers. Hence, it’s imperative for every business dealing with food and beverages to invest in high-quality counting scales.

Using them also enhances operational efficiency by reducing wastage, boosting profits, and increasing customer satisfaction through consistently high-quality products. Moreover, many modern-day weighing scales today come equipped with smart technology for efficient data management that fits into existing processes seamlessly.

Type of Ingredients to be Weighed

The nature of the items to be weighed is a crucial factor in choosing the right counting scales for the food and beverage industry. The weighing process should be able to accommodate different shapes, sizes, and textures of ingredients – considering they can vary greatly from one product to another. Failure to do so may lead to inaccurate measurements and consequent issues in recipe formulation.

- The counting scale must be fitted with a large and durable platform.

- It should have high precision in order to weigh small quantities accurately.

- An efficient tare feature allows for easier calibration when placing multiple items on the weighing scale simultaneously.

- A water-resistant and dust-proof design is necessary for weighing ingredients exposed to wet surroundings, such as fruits or vegetables.

- If bulk storage systems are employed, a counting scale with check weighing capabilities ensures that the correct amount of ingredients is dispensed every time.

- If hazardous or corrosive materials are utilized, the counting scale should withstand exposure without corroding or becoming damaged.

In addition, temperature variations can impact the weight of ingredients during measurement. Therefore, selecting a counting scale with built-in temperature compensation will help ensure accurate readings despite any fluctuation.

Accuracy and Precision Requirements

Accurately measuring ingredients and raw materials in the food and beverage industry is crucial to ensure high-quality products. Therefore, choosing the right scales with precise accuracy and precision requirements is essential. The scales should be able to measure up to the smallest unit required and produce reliable results consistently.

Consistency is vital when it comes to measuring ingredients, making scales’ durability a factor worth considering. It’s also important to ensure that the scale calibration can be adjusted as the weight requirements change over time. A highly durable scale with adjustable calibration will save you money on costly replacement fees and ensure quality products.

Calibrating Scales Regularly

Accurate weights are essential in the food and beverage industry as customer health and safety are at stake. Hence maintaining scale calibration regularly is crucial. Calibration ensures that a scale gives accurate readings consistently.

Here’s a 6-step guide for calibrating scales regularly:

- Ensure the Scale is Clean and Free of Debris: Accumulated remnants on the scale can affect the accuracy of the weight reading. Clean it thoroughly using non-abrasive solutions.

- Use Certified Test Weights: Standardization Institute-certified test weights must be used to calibrate. Place them on the scale and check if the readings match with weight.

- Set up Environmental conditions: Calibrations should ideally happen in a room with minimal external factors like airflow or vibrations that could affect the accuracy

- Adjust Readings: Use calibration software or manually adjust readings to make sure they are consistent with standards set by certification bodies like NIST (National Institute of Standards and Technology)

- Create Record-keeping process: Keep records of calibration dates, test weight use, temperature checks, etc., to ensure that the procedure complies with regulatory requirements

- Frequency Of Calibration Checks: The frequency of checks depends on usage patterns, but it should typically be done every 6 months.

Regular calibrations detect any deviation from ideal results. Detecting any deviation from ideal results often occurs due to changes in humidity levels or wear and tear issues affecting parts that interact directly with measurements. Hence, calibrating scales regularly helps detect deviations early rather than late.

Conclusion

Accurate measurement and quality control are essential in the Food and Beverage Industry. Counting scales play a crucial role in ensuring these standards are met. These scales measure accurately, reducing waste and downtime while increasing efficiency. They also prevent under or over-counting of ingredients, maintaining consistency and product integrity. By utilizing counting scales, businesses can avoid costly mistakes and ensure customer satisfaction with their products. Additionally, these scales can be easily integrated into existing systems, making them an accessible solution for companies of all sizes.