Cannabidiol is one of the few byproducts derived from the cannabis plant. Its uses are widespread and its oil extract has proven effective in treating numerous illnesses, symptoms of cancer and psychological conditions. For CBD oil to reach its final state, the plant must go through a phase of extraction. The type of extraction has a large impact on its purity, quality and overall contents.CBD can be derived from both marijuana and hemp, but legally sold CBD oils are mostly a result of hemp extraction, as it contains a negligible amount of THC (less than 0.3%).

Consuming hemp-derived CBD is widely legal across the States, whereas marijuana-derived CBD often requires a prescription from a medical professional due to its high THC content (5% – 20%).

After you’ve learned more about the various CBD extraction methods, you will have an easier time identifying quality CBD oil by reading the labels. Read on to find out more about the different types of cannabis oil extraction and how it affects the final product.

Supercritical CO2 Extraction

Supercritical CO2 Extraction is the most efficient CBD oil extraction method. The process is based on the use of pressurized carbon dioxide in order to pull out all the vital terpene oils and cannabinoids from the hemp or marijuana plant.

Many CBD extraction methods use various solvents, some of which are harmful to the end product. This may cause the need for additional post-processing. CO2 can act as a solvent by itself at a specific pressure and temperature points. Yet, it does not come with the side-effects associated with different toxic solvents used for extraction.

What’s more, CO2 is considered “tunable”, allowing operators to fully control the pressures and temperature during the extraction process, making room for greater quality control.

The nature of CO2 in its liquid state allows for the creation of pure, top-quality oil with little to no toxins or harmful chemicals that would require additional cleaning. The supercritical CO2 liquid destroys any harmful bacteria, mites, mold and other toxic materials that may have been present on the plant.

As such, Supercritical CO2 is the most commonly used extraction method across the board when it comes to creating quality Cannabidiol oil.

The one downside is that CO2 extractors require a higher initial investment for CBD oil companies, as the equipment is more expensive. Although relevant equipment comes at different price points, the extraction process is slower on cheaper machinery.

On the flip side, if you read the label of your CBD product and find that it’s derived by way of CO2 extraction, you can rest assured you have clean, quality oil at your disposal.

Solvent Extraction

Solvent extraction uses natural solvents or hydrocarbons to separate the CBD oil from the marijuana or hemp plant. The end result is a mix of oil and solvent residue, which means additional post-processing may be required.

Extraction using natural solvents such as ethanol and olive oil comes with no risks of leaving toxic residue in the final product, which is why they’re the preferred solvents for quality CBD products.

Hydrocarbon extraction methods by using butane, propane or petroleum can be quite riskier in comparison to natural solvents. The toxins associated with these chemicals often leave harmful residue in the oil extract, some of which may be risky to your health if not removed properly.

These damaging toxins may be eliminated through post-processing, but a fair portion of the oil’s positive properties will also disintegrate in the process, resulting in lower quality oil and lower production yield.

Ethanol extraction is not without its side effects as well, as the final product is coupled with chlorophyll. While not harmful to your health, chlorophyll affects the oil’s taste which makes it slightly unpleasant for consumption.

Overall, solvent extraction is a less expensive oil production method than CO2 extraction, as it uses more affordable cannabis oil extraction machines. Many businesses, such as capnasystems.com, simplify the ethanol extraction process via advanced machinery optimized for cannabis extraction.

In the hands of a good operator, CBD oil derived by way of ethanol extraction can rival the quality of CO2-derived oils.

The main issue with solvent extraction is the requirement of a disproportionate volume of plant matter to create good quality oil, as a significant portion of the plant’s useful cannabinoids is destroyed during extraction and post-processing.

Steam Distillation

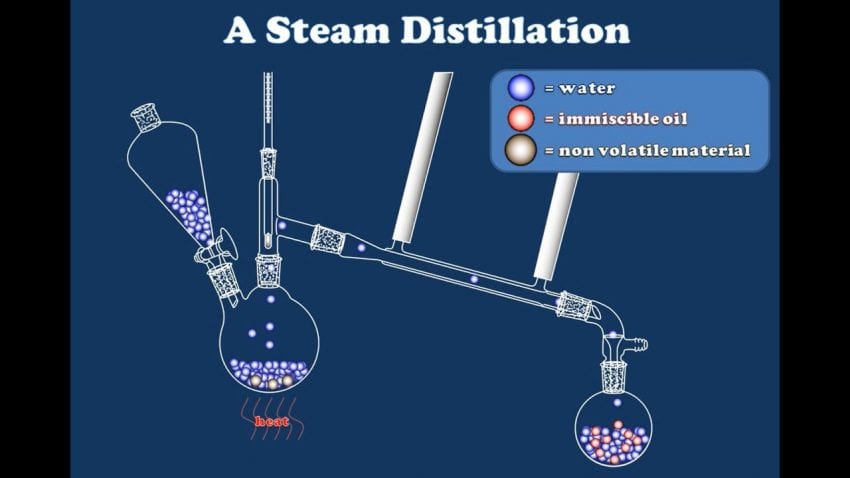

Steam distillation works in a similar fashion as solvent extraction methods, but instead of the use of hydrocarbons or solvents, steam is used to separate the oil from the plant.

For this process, the plant is placed in a glass flask, connected to a glass container underneath that is filled with boiling water. As the water heats up, the steam it generates runs through the glass flask, separating the oil from the plant matter.

An additional outlet in the flask is connected to a condenser tube which collects the final product in the form of oil, while at the same time distilling the remaining water.

Steam distillation is an age-old method used for extracting all types of oils over the centuries, including cannabinoids. While it’s one of the least expensive CBD extraction methods out there, it’s also one of the least efficient ways of acquiring oil. The lack of regulation functions during steam distillation means less control over the exact contents of the final product. What’s more, creating oil through this method requires a vast amount of plant matter in comparison to other extraction techniques.