These components are used to streamline the process of connecting multiple fibers, making them invaluable in data centers and high-speed networks.

Understanding the best practices for using them ensures optimal performance and longevity of the network infrastructure.

Understanding the MPO Connector

The MPO connector is designed to connect multiple fibers in a single interface, typically accommodating 12, 24, or 48 fibers. This design simplifies the cabling process, reduces space requirements, and supports higher data transmission rates. To fully benefit from using these components, it’s crucial to understand their structure and functionality.

Proper Handling

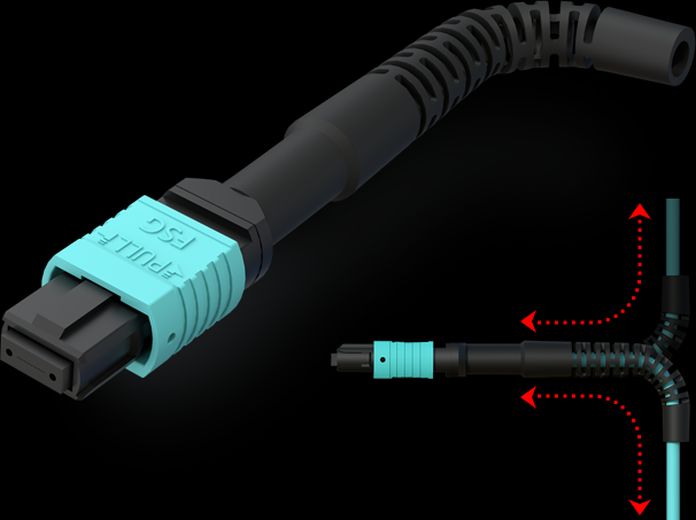

Handling with care is one of the most important things to keep in mind. The device contains multiple delicate fibers, and any mishandling can cause damage, leading to network issues. Always hold the unit by the body, avoiding direct contact with the fibers. Use protective caps when the devices are not in use to prevent dust and debris from contaminating the fibers.

Cleaning Regularly

Regular cleaning is essential for maintaining the performance. Dust and debris can accumulate on the connector end faces, causing signal loss and increased error rates. Use specialized cleaning tools designed for these components, such as one-click cleaners or lint-free wipes with isopropyl alcohol. Ensure that the cleaning process is thorough and that all fibers are free from contaminants.

Correct Polarity Management

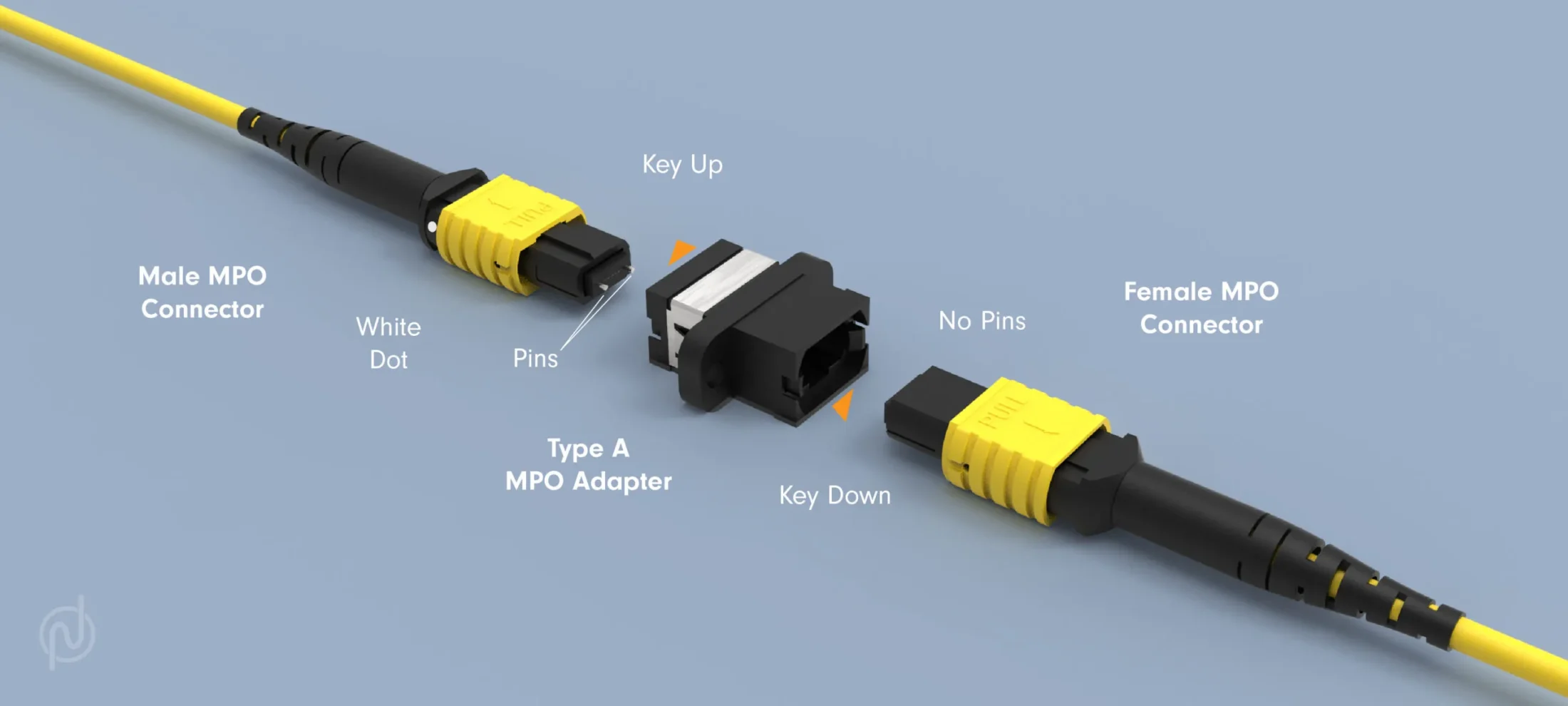

Polarity refers to the alignment of the transmit and receive fibers in a connector. Proper polarity ensures that the signals are transmitted and received accurately. MPO connectors use different polarity methods, such as Type A, Type B, and Type C. Understanding and managing these polarity types is crucial to avoid connectivity issues. Always follow the manufacturer’s guidelines and use polarity testing tools to verify the correct alignment.

Ensuring Proper Mating

The proper mating of these devices is vital for optimal performance. When connecting them, ensure they are aligned correctly and fully engaged. Misalignment can cause increased insertion loss and damage to the end faces. Use alignment pins to guide the component into place and apply even pressure during the mating process.

Regular Inspection and Maintenance

Regular inspection and maintenance help identify potential issues before they escalate. Perform visual inspections using a fiber microscope to check for scratches, cracks, or contamination on the connector end faces. Schedule routine maintenance checks to ensure that all units are in good condition and functioning correctly.

Always Choose High-Quality Components

The quality can significantly impact the performance and reliability of the network. Choose those from reputable manufacturers that adhere to industry standards. High-quality products offer better alignment, lower insertion loss, and increased durability. Investing in premium connectors can save time and money in the long run by reducing the need for replacements and repairs.

Adhering to Bend Radius Specifications

Fiber optic cables, including those with MPO, have specific bend radius requirements. Exceeding these bend radius limits can cause signal loss and damage the fibers. Follow the manufacturer’s recommendations for minimum bend radius, and use cable management systems that support proper routing and organization of the cables.

Labeling and Documentation

Accurate labeling and documentation are essential for managing MPO connector installations. Label each unit and cable clearly to avoid confusion and facilitate troubleshooting. Maintain detailed records of the connector types, polarity configurations, and cleaning schedules. Proper documentation ensures that network technicians can quickly identify and address any issues.

Training and Education

Training and educating network technicians on the proper use of MPO connectors are crucial for maintaining a reliable network. Provide comprehensive training programs that cover the handling, cleaning, inspection, and maintenance of MPO connectors. Regularly update training materials to reflect the latest industry standards and best practices.

Using Protective Housing

Protective housing for MPO connectors can prevent physical damage and contamination. Use protective enclosures and patch panels designed for MPO connectors to safeguard them from external elements. These housings provide additional support and organization, reducing the risk of accidental damage during installation and maintenance.

Testing and Certification

Regular testing and certification of MPO connectors ensure that they meet performance standards. Use optical loss test sets (OLTS) and other testing equipment to measure insertion loss and return loss. Certification ensures that the connectors are functioning correctly and that the network meets industry requirements.

Upgrading and Scaling

As network demands grow, upgrading and scaling the infrastructure may become necessary. MPO connectors support high-density applications, making them ideal for network expansions. Plan upgrades carefully to ensure compatibility with existing components and minimize downtime. Use MPO connectors to simplify the upgrade process and increase the network’s capacity.

Addressing Compatibility Issues

Compatibility issues can arise when using MPO connectors with other types of connectors or network components. Ensure that all components in the network are compatible with MPO connectors. Use adapters and conversion kits if necessary to maintain seamless connectivity and avoid performance degradation.

Cost Considerations

While MPO connectors can be more expensive than traditional connectors, their benefits often outweigh the costs. They reduce installation time, save space, and support higher data rates. Consider the long-term cost savings from reduced maintenance and improved network performance when evaluating the investment in MPO connectors.

Future Trends and Innovations

The future of MPO connectors includes advancements such as higher fiber counts and improved materials. Innovations in connector design will further reduce insertion loss and increase durability. Staying updated with these trends and integrating new technologies will ensure that networks remain efficient and capable of handling increasing data demands.

Conclusion

MPO connectors are critical for modern fiber optic networks, offering high-density connections and supporting rapid data transmission. By following best practices for handling, cleaning, inspecting, and maintaining these connectors, network technicians can ensure optimal performance and longevity.

Proper training, documentation, and adherence to industry standards further enhance the reliability and efficiency of the network. Investing in high-quality MPO connectors and following these guidelines will result in a robust and future-proof network infrastructure.