For more than 70 years, ultrasonic cleaning has been utilized in industrial cleaning. It has become more efficient and powerful throughout time as a result of technology improvements. Ultrasonic cleaners are becoming more popular among enterprises and companies, as they can be more effective and efficient than hand washing or industrial cleaning.

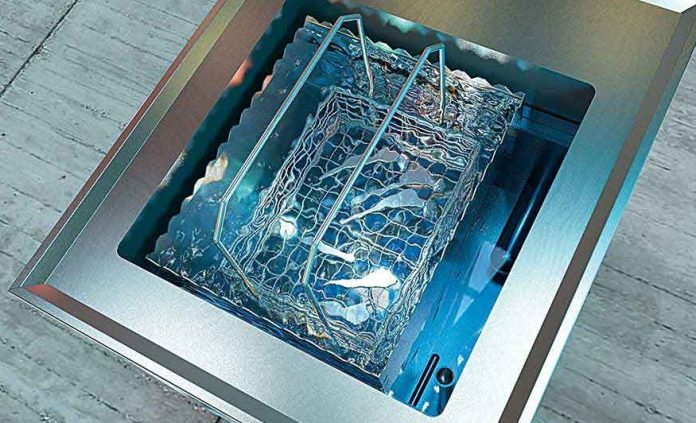

Ultrasonic cleaning removes impurities from solid surfaces by using high-frequency waves and water or a cleaning solvent. Oil, filth, corrosion, grime, and other contaminants can all be removed with ultrasonic cleaning.

Ultrasonic cleaning equipment and accessories are made to make part cleaning easier. Let’s look at why ultrasonic cleaning is superior to other methods for effective cleaning.

1. It Helps You Save Time

Ultrasonic sound cleaning expedites the cleaning process. Cleaning small and complex parts can take a long time. When parts are contaminated with mold, dirt, or other sorts of grime, it takes a long time to clean them up. Ultrasonic sound accelerates the cleaning process.

Cleaning parts traditionally entails soaking them in warm water or a cleaning agent, then vigorous scrubbing. With ultrasonic cleaning, you simply rinse the pieces, place them in the bath, set the timer, and walk away.

The ultrasonic cleaner takes care of the rest. Ultrasonic cleaners can produce up to 40 million sound waves each second. Each pulse thoroughly cleans your parts’ surfaces.

2. It Is Cost-Efficient

Consider the money you spend on chemicals to clean your parts, as well as the money you pay your employees. If you invest in ultrasonic cleaning, your expense will be minimized. It allows you to clean various parts quickly and effectively.

Only one person is usually required to load and unload pieces. As a result, you can save money by lowering the number of staff you have. The money you saved can be used to improve productivity and profit in other areas of your organization or business.

3. Simple To Setup & Use

When you hear the word “ultrasonics,” what’s the first thing that comes to mind? Isn’t it something complex and technical? Ultrasonic cleaners aren’t quite as complicated as they appear. They’re easy to use and understand.

If you need installation or repairs, don’t hesitate to call a professional. You don’t need to engage a professional or enlist the help of qualified individuals to operate and maintain your machine.

4. Easily Clean Difficult Spots

Chemicals and high-frequency waves are both used in ultrasonic cleaning. Every passage, narrow space, and crack will be properly cleaned as a result. Let’s face it, no matter how hard you scrub, you’ll never be able to reach every nook and corner.

You don’t have to be concerned because the human eye cannot perceive every spot of dirt. These pollutants are easily handled with ultrasonic cleaning.

5. Consume Less Power

Compared to other types of cleaning systems, one of the advantages of ultrasonic cleaning is the low power consumption.

Other parts cleaning systems use many motors to pump, spray, circulate, and catch the chemical and its fumes. However, only one motor is utilized in ultrasonic cleaning to filter the solution.

6. Various sizes are available for multiple services.

Ultrasonic equipment is available in a range of sizes from companies like L&R Manufacturing. There is a perfect size for every service, from tabletop sizes to industrial sizes. You can save time and money by not wasting energy and chemicals on a cleaning system that fits all sizes. Ultrasonic cleaners come in a variety of shapes and sizes.

- Ultrasonic cleaners for the table (single tanks ranging in size from half-gallon to 8 gallons)

- Ultrasonic cleaners for the workbench (tanks as large as 20 gallons)

- Industrial cleaners with enormous capacity (tanks as large as 1,000 gallons)

7. Removes Every Kind Of Contaminant

The majority of cleaners have limitations: they can only clean a limited number of pollutants. Ultrasonic cleaners, on the other hand, are a unique type of cleaner.

They can deal with an extensive range of pollutants at once. There’s almost no pollutant that an ultrasonic cleaner can’t manage, including dirt, soot, fingerprints, sand, oil, grease, shavings, charcoal, and varnish.

This is especially useful because some products might collect a variety of pollutants at once. Instead of having a separate cleaning cycle for each type of contamination, an ultrasonic cleaner can remove everything at once.

8. Deep Cleaning

Pulse waves from ultrasonic cleaners come from a variety of directions and move at different frequencies. Parts are cleaned using pressure waves from various directions. This ensures that all of the components are cleaned thoroughly.

To get excellent results from an ultrasonic cleaner, you don’t need to perform multiple cycles. Ultrasonic cleaning is effective even if the item being cleaned has cracks and crevices. Other cleaners do not guarantee this level of excellence.

9. It’s Environment Friendly

Environmentally friendly techniques are becoming more common in today’s enterprises. The chemicals used to make ultrasonic cleaner detergents are non-toxic and environmentally friendly.

Ultrasonic cleaning takes less time and uses less energy; thus, it uses less electricity. You get to conserve the environment in addition to effectively cleaning your parts.

10. Eliminate Bacteria

Bacteria and other pathogens are not removed from surfaces by ultrasonic cleaning. To kill bacteria, you’ll need to apply a strong cleaning solution. It will, however, remove pollutants off the surface of the object you’re cleaning properly. It’s ideal for cleaning medical and dental equipment and gadgets because of this.

Keeping equipment clean is a key responsibility; therefore, no sacrifices should be made. Ultrasonic cleaning has assisted organizations and enterprises in increasing profits by reducing the amount of time spent cleaning items and the number of cleaning personnel required.

Cleaning does not have to be a taxing experience. Many firms are realizing that technology has made industrial cleaning more effective and efficient.

Summing Up

Ultrasonic cleaners have been around for more than 70 years now, and are utilized in a range of industries because they can clean objects so thoroughly. This guide walked you through 10 reasons you should use an ultrasonic cleaner in your business. Hopefully, it’s the incentive you needed to push forward with this venture.