Recycling metals like steel and aluminum plays a critical role in conserving natural resources, reducing energy consumption, and minimizing environmental impact. Both metals are highly valuable in the recycling market, but their profitability varies due to several factors. Understanding these differences can help in making informed decisions about recycling efforts.

However, the infrastructure for “Scrap Metal Recycling Bristol” and similar operations show that the sheer volume of steel recycled can translate to substantial overall profitability, despite its lower price per ton.

Steel Recycling

- Common Sources: Buildings, cars, appliances, and industrial waste. These sources provide a continuous supply of material, making steel scrap readily available. Large structures and vehicles often contribute heavily to the steel recycling stream.

- Recycling Process: Includes collecting scrap, sorting, and melting in a furnace. The sorting process is crucial to remove non-ferrous materials and ensure quality. Melting typically occurs in electric arc furnaces that can reach extremely high temperatures.

- Energy Savings: Recycling steel saves approximately 60% of the energy required for producing steel from raw materials. This substantial energy reduction lowers greenhouse gas emissions, contributing to environmental sustainability. Energy savings also translate into cost benefits for manufacturers.

- Market Volume: Steel is one of the most recycled materials worldwide, with over 630 million tons recycled annually. This high volume stabilizes the market and ensures consistent demand. The global reach of steel recycling underscores its importance in the recycling industry.

Aluminum Recycling

- Common Sources: Beverage cans, food packaging, construction materials, and vehicles. These items often contain high-purity aluminum, ideal for recycling. Lightweight properties and resistance to corrosion make aluminum an excellent material for these applications.

- Recycling Process: Involves collecting and sorting aluminum scrap, then melting it down at a much lower temperature than steel. Precise sorting is necessary to separate different aluminum alloys, which affect the quality of the recycled metal. The melting process for aluminum requires less energy, making it more environmentally friendly.

- Energy Savings: Recycling aluminum saves around 95% of the energy needed to produce new aluminum from bauxite ore. This massive energy saving is crucial for reducing the environmental impact of mining and processing bauxite. Additionally, less energy use means lower emissions and reduced manufacturing costs.

- Market Volume: Significantly lower in volume compared to steel, but highly valued. The high value of recycled aluminum drives its collection and recycling despite its lower overall market volume. Its applications in high-end products maintain its demand and profitability.

Economic Aspects of Recycling

Price Fluctuations

The price of scrap steel typically ranges from $100 to $300 per ton, influenced by global demand and supply. Prices can fluctuate based on international markets and the economic cycle. Stability in steel pricing is often tied to the construction and automotive industries.

Aluminum scrap can fetch between $800 to $1,200 per ton, making it generally more valuable per unit weight. The higher price reflects the demand for aluminum in high-value markets such as aerospace and consumer electronics. Price sensitivity is higher due to its usage in diverse and sometimes luxury products.

Cost of Processing

- Steel: Requires high energy to melt but has a robust and established recycling infrastructure. The infrastructure helps in reducing logistical costs, making steel recycling more efficient. Over time, advancements in furnace technology have improved energy efficiency in steel recycling.

- Aluminum: Lower energy costs for melting, but requires more extensive sorting to ensure quality due to its various alloys. Sorting technologies and techniques are critical to maintaining the high standard of recycled aluminum. Investments in better sorting mechanisms can further reduce costs and increase the value of the final recycled product.

Demand in Market

Steel

Constantly high, especially from construction and automotive sectors. Its strength and durability make it indispensable in infrastructure projects. Fluctuations in these sectors can impact steel demand but usually remain strong due to ongoing development worldwide.

Aluminum

High in specific markets like beverage packaging and lightweight automotive components. The push for lighter vehicles for better fuel efficiency boosts aluminum use. Additionally, the consumer preference for sustainable packaging solutions drives aluminum demand in the packaging industry.

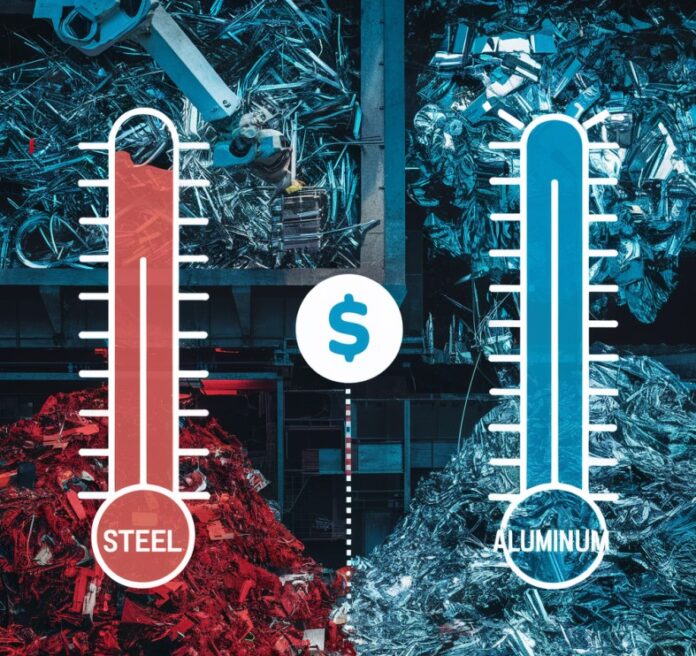

Comparing Profitability

Unit Value

Per ton, aluminum tends to be more valuable. This higher unit value makes it particularly attractive in terms of return on investment for recycling operations. The premium on aluminum often reflects its versatility and desirability in various high-tech and consumer products.

Volume and Availability

Steel scrap is more abundant and frequently recycled, potentially leading to higher overall revenue, even at lower prices. The sheer scale of steel recycling operations can compensate for the lower price per ton. Bulk recycling facilities often handle large quantities of steel, making it a staple in the recycling industry.

Regulatory Influences

- Steel: Various international and national regulations that encourage the recycling of materials like steel can impact profitability. For instance, some regions offer tax incentives for companies that engage in the recycling of metals, which can lower operational costs and increase profit margins. Furthermore, environmental regulations requiring reduced emissions encourage industries to use more recycled steel.

- Aluminum: Aluminum recycling is often subject to stringent quality and safety standards, particularly in food and medical applications, which can influence the profitability of recycling operations. Compliance with these regulations can require additional processing steps or more sophisticated technology, potentially increasing costs but also ensuring access to high-value markets.

Innovations in Recycling Technology

Technological advancements have improved the efficiency and effectiveness of steel recycling processes. New sorting technologies, such as magnetic separation and advanced spectroscopy, have made it easier and cheaper to separate and recycle high-quality steel. These innovations not only reduce processing costs but also enhance the quality of the recycled steel, making it competitive with virgin materials.

In the case of aluminum, recent developments in thermal and mechanical recycling processes have allowed for the recovery of aluminum from more complex waste streams, such as laminated packaging and mixed materials. These technologies help in maintaining the purity and properties of recycled aluminum, which is crucial for its reuse in sensitive applications like food packaging and aerospace.

In Summary

Aluminum often shows higher per-unit profitability in recycling due to its higher scrap value and lower energy costs. However, the vast amount of recycled steel means it can also be highly profitable, especially in volume-driven markets. The choice between focusing on steel or aluminum recycling should consider local market demands, available recycling infrastructure, and the scale of operations.

By understanding these dynamics, recyclers can optimize their operations to maximize profitability while contributing positively to environmental sustainability.