A warehouse of a company or a factory is typically the place where its inventory is stored. It is needless to say that the management of the warehouse is a crucial part of the supply chain management of any business.

If you are not adept at managing your inventory, your company may be in big setbacks. So if you want an intelligent and flexible Warehouse Management System for your company, then look for some latest software or applications.

However, if you are not yet ready to shift to software, then this article gives you a few quick and easy-to-implement tips that will improve your company’s productivity.

Some Quick Tips To Improve Warehouse Layout Management

Analyze The Flow Of The Warehouse

Before you make any changes to the layout of your Warehouse, you must know the flow; that is how the volume of goods that moves in and moves out from the warehouse. Now depending on the type of your business, you could have a turnover of goods every single day, or you could have a turnover every few weeks.

So depending on your turnover period, analyze the flow of goods. Analyzing the flow of goods is essential. If you do not have a precise idea of how many items leave the stock and how many of those are replaced in a given period, you will never be able to optimize the space utilization and logistics management of the warehouse.

If your company has a single supplier and a single distributor, then analyzing the flow of goods is quite easy. However, in most real-life scenarios, a company has multiple distributors and suppliers and so things are slightly more challenging.

You may have a daily contract with one supplier and a weekly contract with another. So, in that case, you will have to keep a check on the flow of goods till the time the last supplier supplies and the last distributor clears out the goods.

Pay Close Attention To The Kinds Of Goods That You Wish To Store

Every warehouse is different because the type of goods each industry needs and stores is quite different from each other. So it is needless to say that depending on the kind of goods that you are storing as your inventory, you need to plan the warehouse accordingly.

So, for instance, if your main business involves value addition to some basic raw material, then your warehouse should have a designated place for the value addition. If you buy plain shirts from a wholesale shirt supplier and then your main business is to design or print those shirts there, you should have adequate provisions for designing in the warehouse itself.

Typically where a business is into value addition, they prefer an L-shaped design for storing their basic stocks. In an L-shaped design, the horizontal edge of the L is used for storing the basic raw material and the vertical edge is used for value addition or vice versa.

Again if your main business involves storing raw materials that are perishable or those that get destroyed when exposed to excess cold, you have to make arrangements accordingly. So considering the basic needs of your business and the type of raw material you use is essential before you start changing the layout of your warehouse.

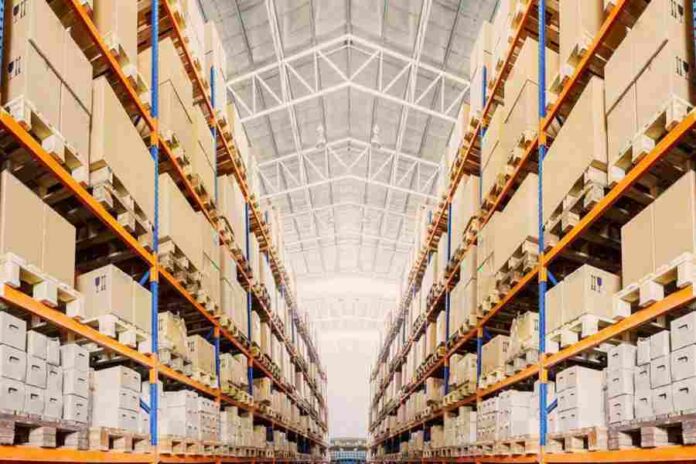

Focus On The Storage System

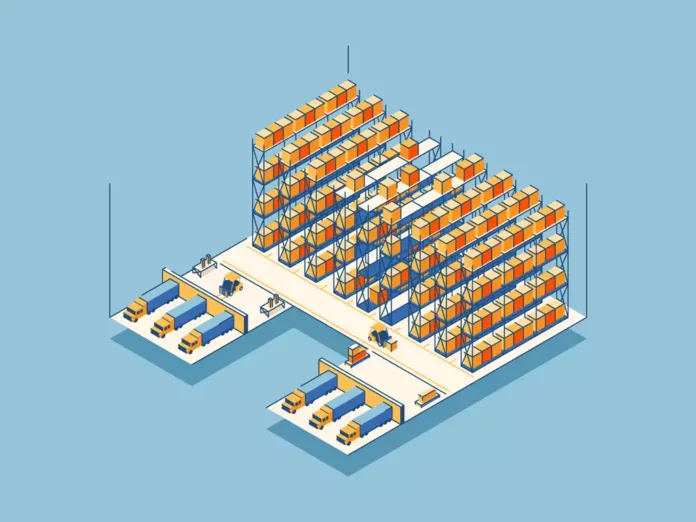

In a storehouse of goods, you have to pack and stack things effectively if you are to optimize space utilization. So you have to make the right choice of storage system. You may have to make a choice between manual and automatic storage systems.

Manual storage is a cheaper alternative. In this case, your employees have to physically stack goods or move goods from one place to another. So it will take a lot of time to physically move the items from one place to another. However, if you go for the automatic system, it will make use of modern conveyor belts and cranes to stack and move the goods within the warehouse.

Automated systems are more expensive, but they are much more efficient, and they ensure the safety of your employees. The software can control all the movement within the warehouse, and thus chances of mistakes are replaced to a great extent.

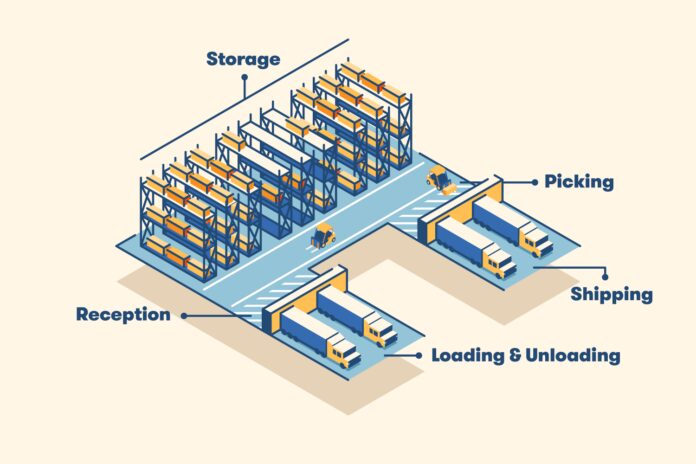

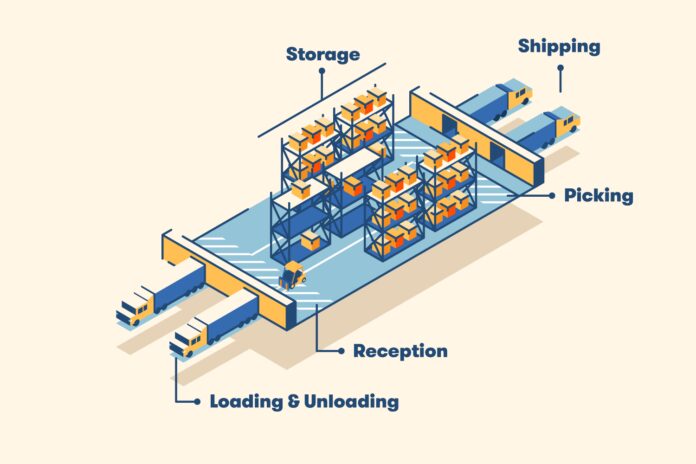

Create Different Zones For Different Activities

A warehouse should be divided into specific areas to streamline all the work. Usually, there are four to five areas. First is the goods receipt area; this is the area where the supplier supplies the raw material. This is the busiest part of the entire warehouse, so a large area should be designated for the receipt.

Then you need designated spaces for the storage of goods, spaces for additional processing, and space for quality control. And finally, a space for the supply of finished products. Designate zones and employ key personnel in different areas to streamline the process and improve the turnaround time of products in your storage facility.

Plan For Additional Activities In The Near Future

Most businesses try to expand their operations with time, so you should always try to keep some space for expansion. In the future, you may start some new kind of value addition, or you may need to store more products. So it is always prudent to keep space designated for future expansion.

Conclusion

Proper management of your storage space makes it easy to monitor the number of goods that are being received or supplied. So the chances of leakages or damages are reduced to a minimum. If loss and damages are reduced, then your business runs more smoothly.

Today most companies go for warehouse management software that makes their lives easy and brings automation to the handling of goods stored in a storehouse. And if you can afford the software, they are definitely worth giving a try. Good software may be expensive in the short run, but it will improve your profit margins and reduce your losses in the long run.