Maintaining accurate inventory records is essential for having clear insight into what stock is available and what needs to be ordered. At the end of the day, an incorrect inventory count can lead to disappointed customers, and that’s never ideal.

Accurate inventory counts offer the following benefits:

- Your operations will run smoothly

- Your cost of carrying goods is reduced

- Customers are happy

- Employees can support your customers better

- More accurate forecasting

If you’ve noticed your inventory counts aren’t as accurate as you’d like, and you’re looking for ways to improve, the following tips will give you a great place to start.

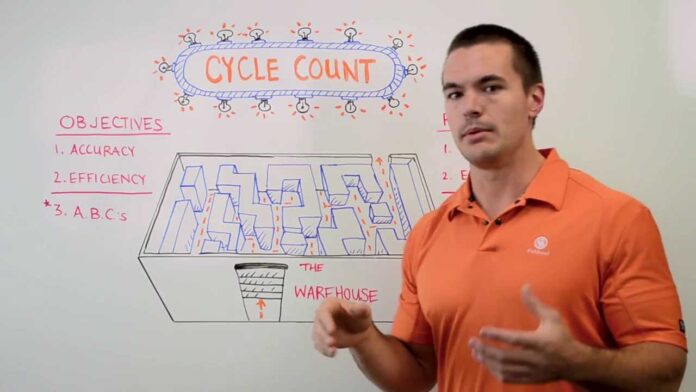

1. Implement cycle counts

Cycle counts are great when you can’t pull people off the floor to count inventory in full. This is a process where you perform regular counts for certain inventory to make sure it matches your inventory records. However, it’s not done all at once, and only periodically. It’s more of an audit than a full inventory count.

Cetaris explains that cycle counts are performed over a period of time, but they’re tailored to count your most important items, like parts that are critical to your business processes. However, you’ll need to have clear business goals in order to figure out what is most important.

A simple way to implement cycle counts

There’s a simple way to implement cycle counts within your organization. Create at least three categories for groups of items based on their importance. For instance, determine which items are most important, and label those “Category A.” Then, determine which items are “Category B” and “Category C.”

Create a system and schedule where you count “A” items most frequently. This might be once a week or two. Then, determine when you’ll count “B” and “C” items. Perhaps once every three to six weeks – whatever schedule works best for your needs.

There are other cycle count methods you can use, but this method is the simplest.

2. For small inventory, implement daily counts

Have you considered implementing a daily inventory count in your store? Depending on how much inventory you keep on hand, this could be the key to improving your count accuracy.

Daily inventory counts can be a pain for employees, so it’s important to make sure it’s possible and won’t get in the way of their other duties. If counting inventory daily seems like an issue, schedule it for after the store is closed and make sure you still give people enough time to complete their normal closing duties.

If you’re hesitant to do daily inventory, consider that there are many popular companies that perform daily inventory counts. For example, Starbucks requires shift supervisors to count milk, pastries, and certain snacks daily. Daily inventory counts will also help keep your ordering on track, which brings up the next point.

3. Get a handle on your ordering process

Your ordering process plays a huge role in keeping accurate inventory. If your inventory counts are entered into your ordering system, inaccurate inventory numbers will create inaccurate ordering, which in turn will perpetuate inaccurate inventory counts.

If your employees enter inventory counts into a software program, and you use that information to place orders (automatically or not), you need to fine-tune your process. Inaccurate inventory counts are common, but can be fixed when you get to the root of the problem.

4. Find the root of inaccurate inventory counts

If your employees aren’t submitting accurate inventory counts, there is probably a good reason. One of the biggest reasons employees fudge inventory numbers is because they don’t have time to perform an accurate count.

Talk with your employees and work with them on the floor so you can see exactly what it takes for them to get an accurate inventory count. If it’s too much to ask them to be available to customers, then you’ll need to schedule them off the floor so they can get accurate counts.

5. Hire an outside team to count inventory

If you’re struggling with getting accurate inventory counts from your in-house employees, try hiring an outside inventory counting company. People in this profession are experts at what they do and can learn any inventory system fairly fast. As they come back to perform more counts, they’ll become more familiar with your systems and business and this will benefit you greatly.

Inventory specialists have an eye for details and can work their way through the toughest stockroom, calmly and methodically. They are adept at multitasking and can work under great pressure.

When you hire a professional team to count your inventory, they won’t take the shortcuts your employees might take just to go home sooner. For instance, employees might try to guess how many items are in a bin by sight out of familiarity, but an inventory specialist won’t. They know that if they get audited and their counts are wrong, they won’t be getting anymore gigs from you.

6. Prevent over-ordering

The more items you have to count, the longer it will take, and the more room there is for error. If your team members have an enormous number of items to count, miscounts are inevitable. They might even skip the task or guess instead of really counting.

The best thing you can do to support accurate inventory counts is to create an accurate ordering process. Figure out what you need to keep on hand and work out a system to ensure your team doesn’t over-order.

When you have a lot of items in your inventory, your cash flow is tied up in goods that aren’t moving. If you need your cash for other things, this can become a huge hang-up when you have a significant amount of money tied up in excess inventory.

Take control of your inventory

If your inventory counts have been off, it’s time to reign them back in and take control of your counts. Regardless of your preferred method, start implementing an inventory counting system that works best for you. Your employees will thank you and your customers will benefit in the long run.