Thanks to the rise in 3D printers, anyone with the knowledge of computer-aided design can come up with an idea and bring it to life. These printers operate similar to the way traditional printers print off files, creating 3D objects from digital files and special “ink” that prints liquid but solidifies as it cools.

With a vast amount of information readily available online, you don’t need to be an avid tech enthusiast like our friend and collaborator Austin Alexander Burridge of Rosemount, Illinois to learn how these printers work.

So, if you’re a novice when it comes to 3D printers and unsure of where to begin, fret not. Simply read on to sink your teeth into our printing overview that we did in collaboration with Austin Alexander.

How Do 3D Printers Work?

The first step in 3D printing is creating a digital file, which is a blueprint for the object that’s being printed. Once created, a digital template can be reused time and again to ensure reliable and accurate objects, such as replacement parts for appliances or custom printed toys for kids.

Alternately, unique files can be developed for single-instance iterations, as in medicine, when a patient may get a custom knee replacement using a printed model.

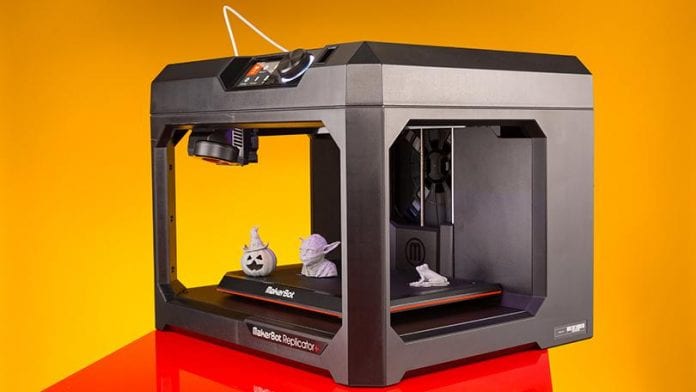

In both cases, the appeal is the same: custom parts can be created (or replicated) on demand. A few of the industries that rely on printed parts include automotive, aviation, appliance, healthcare, and entertainment.

The 3D Printing Process Explained

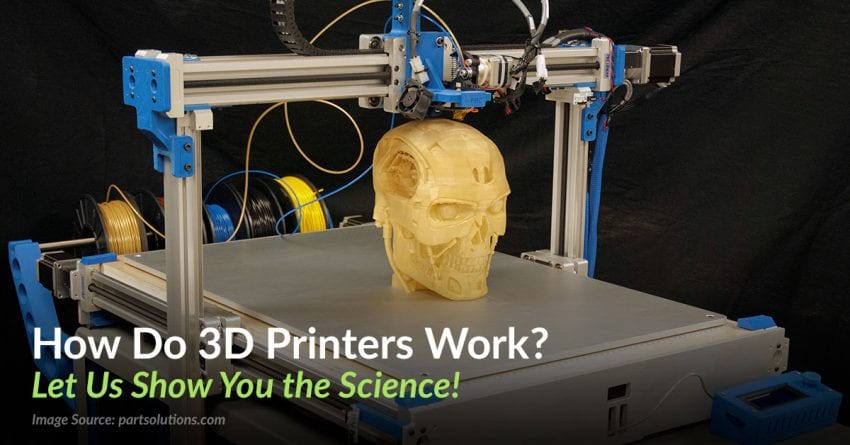

Before the printer can print out the object, the 3D file is broken down into two-dimensional slices. As the 2D slices are stacked on top of one another in the printing process, the object takes on three dimensions.

The printer either emits a special liquid ink that solidifies as it cools or uses a powder ink that turns solid as it is heated. The individual laters fuse as the layers solidify, creating a strong object.

In some cases, 3D printers print with edible ink, using foods such as cheese or chocolate that flow in a liquid state and turn solid at room temperature. Since these printed items can be very complex, printing time varies. A simple job may take a few hours to complete, while something complex can require several days to print fully. As these printers become more commonplace, the cost of 3D printed items goes down, and the convenience factor increases exponentially.

It’s easier than ever to find 3D printers and supplies so whether you’re a business looking to offer printed parts, an artist interested in creating unique 3D artworks, or an individual hobbyist, you can get started quickly–and the sky’s the limit in terms of what you create!