In the past, electronic devices consisted of various components that were connected by soldering to terminal strips, tube sockets, or each other. Vacuum tubes were major and were used in numerous devices as opposed to today, where printed circuit boards have enabled a cheaper and more efficient way of connecting said components.

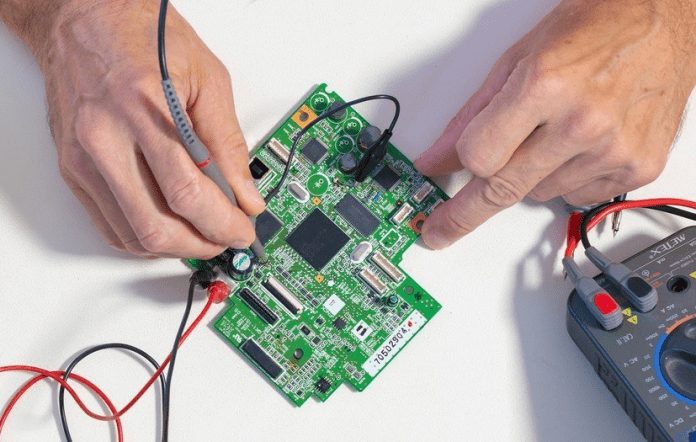

Often referred to as PCBs, printed circuit boards are made from an insulating material, its surface coated, sometimes both the top and bottom, with a metal. Pathways for electricity to travel between the components are made creating etches in the metal using acid. The components are then mounted on the surface of the board by soldering.

These boards have various applications and are often used in numerous products, such as in medical devices, LEDs, industrial equipment, as automotive and aerospace components, in telecommunication equipment, and many more. So let’s take a look at their advantages and why they are commonly used in various electronic products.

1. Fixed Components

The assembly process makes sure that all of the components are permanently fixed onto the board. There is no need for complex wiring systems and its simple design makes it easier to maintain and manipulate it according to one’s needs. This also makes the components immune to movement.

2. Tight Connections and Minimized Short-Circuiting

Through copper tracks, tight connections are made automatically, eliminating the possibility of loose connections and lessening the chances of short circuits.

3. Cost-Efficient and Reliable

In a single production run, you can create several PCBs as long as you have a finished working design, meaning you can save a great amount of money even when you mass produce. This is because it hardly requires any manpower since all you have to do is load the design into a computer and wait for it to print and etch onto the copper board. To learn more about this, you can visit www.pcbonline.com.

The boards undergo strict inspections throughout the production process, eliminating the need to worry about poorly designed components or sudden short circuits. The fully automated production procedure is another reason why they are extremely reliable.

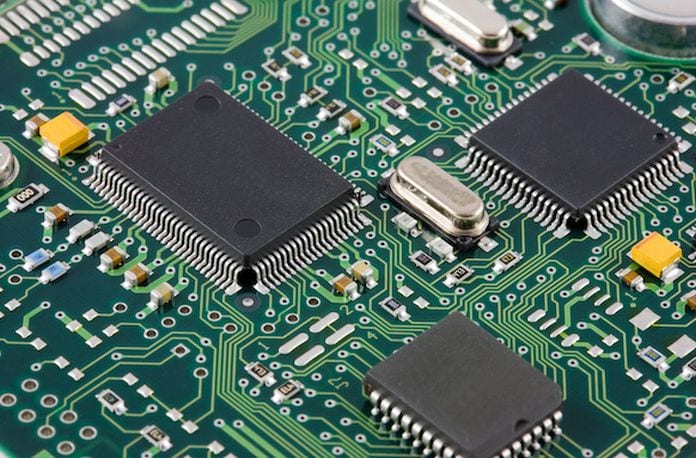

4. Compact in Size

Most of the electronic parts that are mounted on the board are very small and arranged in an efficient, compressed way. This enables the creation of complicated, big circuits that are small in form, meaning that they also take less space in devices.

The interconnection between the components is made through copper tracks as opposed to using numerous current-carrying wires which makes them less bulky and enables the saving of wire.

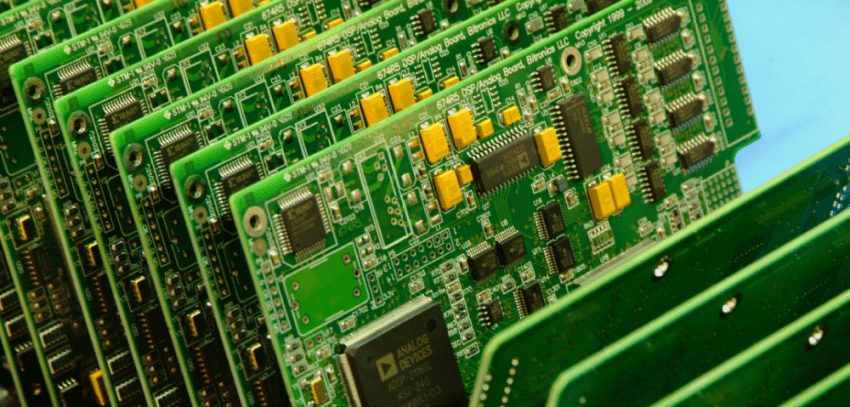

5. Unlimited Reproduction Capabilities

The convenience of the reproduction process saves a lot of time and money since once a design is saved onto a computer, it can be reused and reproduced as many times as one wants. It is perfect for making several batches of identical boards.

Conclusion

Consistent performance is crucial to all modern electronic devices and that is something printed circuit boards provide. Their numerous benefits and advantages are the main reason why they are used in a wide range of electronic products today.