Now, if you are in the manufacturing industry you surely know that the process of developing any prototype is quite complicated, yet you want to make it as effective as possible. And apart from saving on time, you would want to find a process that is cost-effective as well. Though machines and equipment operated by engineers do have their benefits those methods require additional employees and the work time is limited due to the fact that employees have to take a break. On the other hand, if the machine was able to work for itself 24/7 that would be the perfect match right? Well, it is possible, and computer numerical control machining provides that.

If you own a company that develops metal or plastic parts and prototypes and needs to improve your production, CNC machining can be a game changer. Investing in this kind of machines or paying for a service to be done by a third-party seems like your go-to option. But what is it exactly, and how can it benefit the effectiveness of your company’s production. Let’s go ahead and take a look.

How Do CNC Machines Work

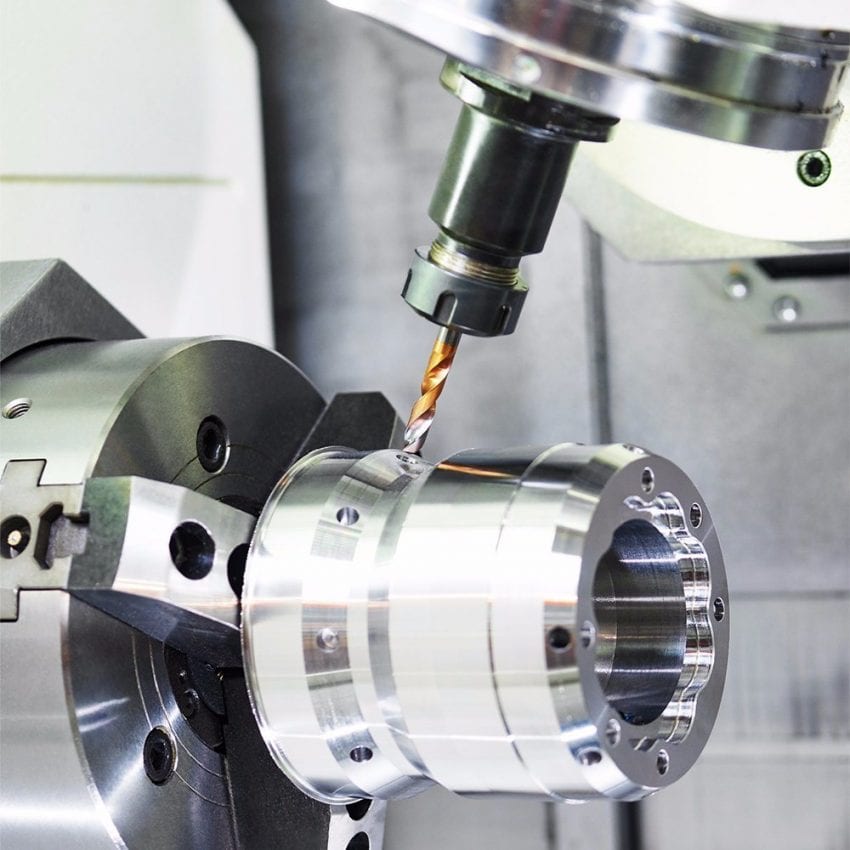

As mentioned above CNC stands for computer numerical control and it includes a computer controlled machining system that can cover numerous tools and activities. Now, one of the biggest benefits is the fact that a CNC machining uses a well-developed programming language that allows for the best precision possible. And though it looks like a normal computer from the outside, it is there to control a complete machining center – determining where to cut, at what rate, for how long, and at what shape. The CNC machining can be a game changer and big names in this industry have instantly started applying it as a go-to option.

If you have a computer expert in your team, installing the CNC machining shouldn’t be a problem, but you should still go and perform a trial run just to be sure that it will not terminate any product that might be under its work. The trial process that is performed is called air cutting and is usually done only once – at the beginning of the manufacturing process, to notice and correct any possible mistakes that were set in the programming.

If you don’t want to invest in CNC machining set, there is still an option for yourself. You can hire some of the relevant services like ArtMachining is, that will be there to provide you with high-quality manufacturing and send you the wanted prototype parts in a matter of a few days. Mostly using materials such as aluminum or stainless steel, the CNC machining services are of great benefit if you don’t have enough space to own one yourself, or you think you are better of getting this job done by a third-party.

This kind of agency includes both the turning and milling services, and you are sure to receive the wanted prototype parts that are up to your requirements. And for more information check out artmachining.com

Summary

CNC machining is without a doubt one of the most effective solutions if you are in the manufacturing industry. If you decide to set up one for your company it will be one of the best business moves you can make, while on the other hand, you can decide to try it out by hiring a third-party CNC machining service that will manufacture the parts for you at a fair and a reasonable price!